Production technology

Adhesives

Cleaning products

Dissipation thermique

Dosing systems

ESD products

Extraction accessories

Extraction filter systems

Flux

Hand tools

Ingot plumb bob

Inspection systems

Maintenance aids

Measuring tools

Occupational safety

Potting compounds

Protective coatings

Protective equipment

Repair stations

Rework stations

Solder bars

Solder pastes

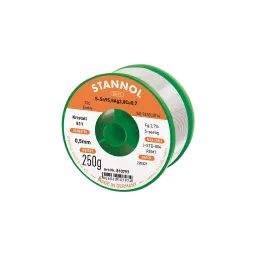

Solder wires

Soldering accessories

Soldering stations

Soldering tips and nozzles

Soldering tools

Suction accessories

Suction filter systems

Vices

About the product

Trilence solder wire is a development for demanding tasks in machine soldering, hand soldering and rework. Its greatly reduced spattering behavior leads to a reduction in cleaning effort with improved soldering behavior. The wire flux Trilence achieves its optimized properties through a halogen-activated composition based on synthetic resins.

Technical data

- Minimal splash tendency

- Very good wetting

- light-colored residues

Areas of application

Trilence can be used in all areas of electrical engineering and electronics for hand and machine soldering. The extremely low spattering behavior, the bright clear residues and the good spreading characterize it for the most demanding soldering tasks.

Product specifications

| Manufacturer | STANNOL |

| Melting temperature (°C) | 217 °C |

| Proportion of copper (Cu) | 0.5 |

| Proportion of silver (Ag) | 3 |

| Proportion of tin (Sn) | 96.5 |

| Alloy | Pewter/silver/copper |

| Coil size (g) | 500 g |

| Flux | REM1 |

| Diameter | 0.5 mm |

| Fairtin | No |

| Halogen-free | No |

| Leaded | No |

| Product series | Trilence 2708 |

Data sheets

Accessories

Related products

Log in

Sign in for full site access, including pricing, ordering, product customization, and more.

Log in