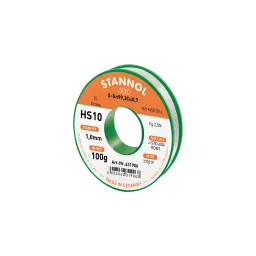

About the product

The electronic solder wires in the Stannol KS series are products that have been developed to meet the high demands of soldering with lead-free alloys. They therefore meet the demands placed on a solder wire in industrial production, machine soldering as well as repair and re-soldering.

Stannol KS115 contains a halogen-activated and rosin-free flux with synthetic resins. Stannol KS100 is based on the same resins, but is halogen-free activated. All flux types combine excellent high activity and thermal resistance with bright, resinous, solid and electrically safe residues. The Stannol KS115 wire flux complies with J-STD-004 and is classified as REM1 due to its high activation (1.5%). The Stannol KS100 corresponds to J-STD-004 type REL0.

Technical data

In contrast to natural rosin, the synthetic resins used in the flux offer the following advantages:

- Active flux (fast wetting of soldering surfaces; shorter cycle times)

- Light-colored residues (low thermal degradation of the resin at high temperatures; visually good impression)

- Solid residues (high softening point; chemical-physical safety)

- Less spatter (higher viscosity of the flux at soldering temperature; less contamination)

- Less fumes (low decomposition and evaporation at high temperatures; reduced workplace pollution and contamination of the solder joint environment)

Areas of application

Stannol soldering wires KS115 and KS100 can be used for hand and machine soldering in the field of electrical engineering and electronics.

Product specifications

| Diameter | 1.2 mm |

| Proportion of tin (Sn) | 95.5 |

| Proportion of copper (Cu) | 0.7 |

| Coil size (g) | 100 g |

| Melting temperature (°C) | 217 °C |

| Alloy | Pewter/silver/copper |

| Product series | KS100 |

| Flux | REL0 |

| Halogen-free | Yes |

| Fairtin | No |

| Leaded | No |

| Manufacturer | STANNOL |

| Proportion of silver (Ag) | 45872 |

Data sheets

Accessories

Related products

Log in

Sign in for full site access, including pricing, ordering, product customization, and more.

Log in